Mandrel and T-Bend Testers

The main similarity between mandrel bend testers and T-bend testers is that both are used to evaluate the flexibility and adhesion of coatings on metal sheets by bending the coated material and assessing for cracks, flaking, or detachment. Both methods help determine how well a coating can withstand deformation without failing, making them essential for testing coating performance in applications where flexibility is important.

The mandrel bend test evaluates the flexibility and crack resistance of coatings on metal or rubber substrates by bending the coated panel over a conical or cylindrical mandrel. This test is commonly used in automotive and metal packaging industries to ensure coatings withstand bending during manufacturing or assembly.

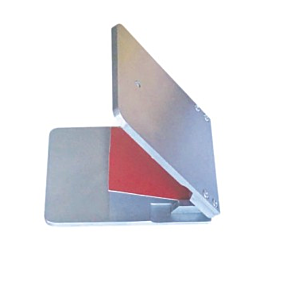

The T-bend test assesses the flexibility and adhesion of coatings on metal substrates by bending the coated panel 180° back on itself, with the coating on the outside. This method is widely used in the appliance and construction industries to verify that coatings remain intact and adhere well after bending.