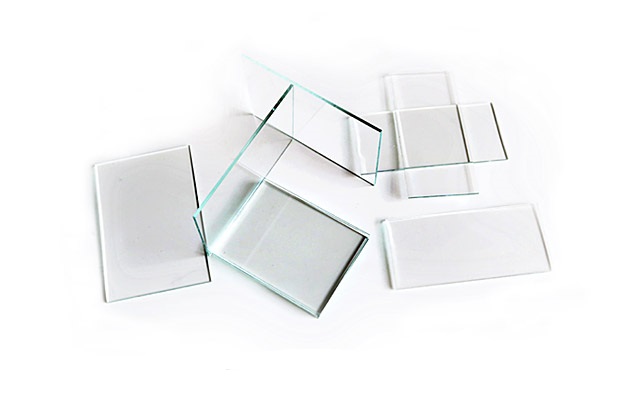

Glass Test Panels

Glass is considered a good substrate for paint testing due to several key characteristics that influence the interaction between paint and the surface. Here are the main reasons:

- Non-porous Surface

- Smoothness and Flatness

- Chemical Stability

- Thermal Stability

- Ease of Surface Preparation

- Application Versatility

In standards such as ISO 1522, which pertains to the pendulum damping test for paints and varnishes, the recommended substrates are primarily metal or glass panels. These panels must be plane, rigid, and free from distortion to ensure accurate testing results.

GB/T 1730 "Paint Film Pendulum Hardness" and GB/T 1768 "Paint Film Abrasion Resistance Determination Method," along with other standards, require the use of glass plates as test base plates. The test-grade glass plates provided by Solvica fully comply with the technical requirements outlined in GB 4871. Additionally, the surface treatment of these plates adheres to the specifications of GB/T 9271, utilizing a solvent cleaning method.

| Product description | Dimensions | Main applications | Quantity (pcs per box) | |

| BGD 2600-2 | Glass Panel (2 mm thickness) |

120mm x 90mm

|

Pendulum Hardness Testing (BGD 509) | 100 |

| BGD 2600-3 | Glass Panel (3mm thickness) | |||

| BGD 2601 | Glass Panel with circular hole | Diameter Ø100mm; center hole Ø 9mm | Rotational Abrasion Testing (BGD 522 & 523) | 100 |

| BGD 2602 | Special Glass Strips | 300mm x 24 mm | Drying Time Testing (BGD 261 & 262) | 60 |

| BGD 2603 | Glass Panel (3mm thickness) | 150mm x 100m | General Purpose | 100 |

| BGD 2604 | Glass Panel (3mm thickness) | 150mm x 70mm | General Purpose | 100 |